Here’s how it works: The fabric to generally be dried is placed within a mattress, and incredibly hot air is blown from underneath.

We purpose to reveal the protected techniques in the engineering sector by in-depth guides and informational articles addressing the information asymmetry that has stifled innovation.

Bühler Team: Recognized for offering system answers inside the fields of food and feed manufacturing, and they also offer fluidized bed drying technologies.

The FBD process is greatly useful for drying APIs, making certain their balance and shelf-everyday living. The fluidized bed permits uniform drying, avoiding the development of incredibly hot spots and making sure regular merchandise top quality.

Principle Fluidized bed dryers : A fluidized mattress dryer aka. FBD is actually a system in which the reliable particles are partially suspended in an upward-moving fuel stream handed by way of a perforated bottom in the container.

Frequent upkeep and cleansing with the fluidized mattress machines are essential to make certain its effective operation.

Periodically performed deep cleansing like disassemble device, soak filters, and wipe down all surfaces with ideal cleaning agents.

Fluidization: The hot air flows throughout the perforated base with the bowl with a predetermined air velocity which is little by little improved in a few minutes.

Pharmaceutical companies immediately observed the opportunity for swift and Light drying of granules and powders, changing slow and uneven tray drying check here solutions.

Horizontal FBD is much more ideal for drying batches of greater volumes that demand a continuous drying cycle. Generally, these dryers require a massive financial investment to purchase, work and maintain.

Integration with wise systems and the usage of Innovative resources will Engage in a crucial position in shaping the way forward for fluidized mattress drying techniques.

To grasp fluidized mattress dryers, it’s initially essential to be aware of the strategy of ‘fluidization’. Fluidization is click here actually a process that minimizes the resistance of sound particles and enables them to exhibit fluid-like properties.

The precondition for an air heating device will be to warmth the primary tower. Compression air inspection is completed to assure that joints shaped by inflation gaskets are leakproof.

Rapidly Drying with Minimal Warmth: FBDs are usually operated with Incredibly hot Air as being a drying media. Because of the fluidization, the recent air can certainly go over the big surface area place of each granule Or powder particle, hence, the drying results in being extremely powerful inside a minimum span of your time.

Bradley Pierce Then & Now!

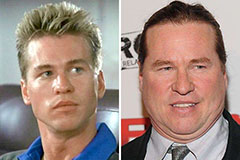

Bradley Pierce Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!